-

Propietary Products

Propietary Products

Our speciality is the development and manufacture of precision parts and assemblies with break-off, tear-off or twist-off zones in all injection-moldable materials.

- Solutions

Solutions

A question of perspective:

You might think we can't do much ... just plastic parts for use in the medical industy.

On the other hand, we can do nothing better than that: we concentrate on our core competencies.

Without compromise - best quality - at a reasonable price - Made in Germany

Together with our customers, we develop precision parts, assemblies and ready-to-use packaged complete systems from the idea to series production.- About us

- Quality Management

- Career

- News

- Contact

Mold Shop

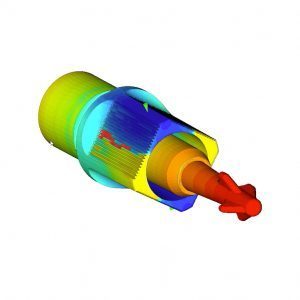

Plastic parts for medical technology require the highest precision - and that relies on precise moulds.

Mold Shop

Thanks to our experience in the design of moulds with the finest predetermined breaking points, the tightest tolerances or a multitude of other, product-specific requirements, our moulds guarantee a consistently and permanently high quality of your products.

Technical know-how and optimal equipment are crucial for the production of precise injection moulds. Our state-of-the-art processing technologies and our 3D measuring machine guarantee the highest quality of mould and article.

In-house design is our strength - for articles and mould concepts as well as from development to sample moulds and series moulds. We are at home in thermoplastic 1k and 2k injection moulding as well as in silicone LSR injection moulding (temperature and post-processing-free medical silicones).

In Spang &Brands own sample models, we can flexibly produce sample inserts for your articles.

For the production of precision tools, we manufacture all tools and moulds with our high-quality machines in milling, eroding, wire cutting and grinding - naturally under air-conditioned conditions. This is the only way to achieve the required manufacturing precision in the μ-range.

The use of the latest machining technology for optimised production and maximum precision of the tools - and of course an air-conditioned measuring room & 3D measuring machine for checking the individual parts - is a prerequisite for the repeat accuracy of your articles in production. After the tools have been manufactured, the service staff takes care of the maintenance and repair of your tools.

This is basically our standard in our services for you - and regardless of whether you want a complete package or an individual configuration.

Contact

Tel.: +49 6172 9570-0

E-mail: info@spang-brands.de

- Solutions

2port caps

2port caps

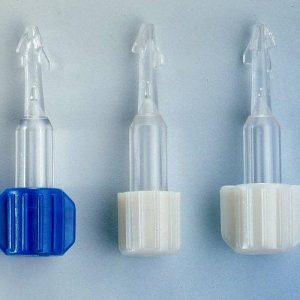

Breakable caps, assembled

Breakable caps, assembled

Tamper Proof Caps

Tamper Proof Caps

Steril Connector

Steril Connector

Product Development

Product Development

Mold Shop

Mold Shop

Injection Moulding

Injection Moulding

Clean room Assembly

Clean room Assembly